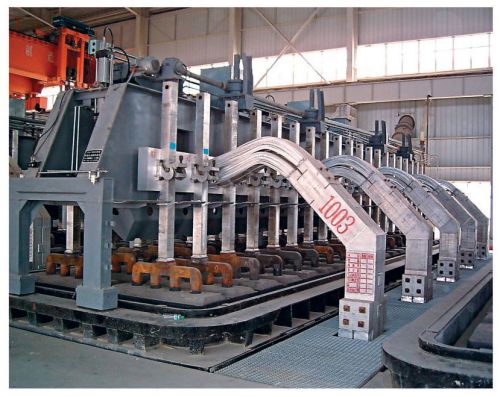

Hengfengtai entered the field of electrolytic aluminum in the 1990s. In 1997, Hengfengtai developed a 60KA lifting mechanism. In 2001, Hengfengtai successfully developed the first domestic 300KA electrolyzer with eight-hanging point hoist and the first domestic horizontal and vertical adjustable busbar conversion frame. In 2008, Hengfengtai's "eight lifting point anode lifting mechanism for electrolyzer" was listed as a national key new product. Hengfengtai, with nearly 30 years of professional experience in R&D, design and manufacturing of complete sets of equipment in the aluminum industry, has always been at the forefront of the industry. Over the years, Hengfengtai has also cooperated closely with well-known scientific research institutes in the industry such as the Institute of Electrical Engineering of the Chinese Academy of Sciences, Guiyang Aluminum and Magnesium Design and Research Institute, Shenyang Aluminum and Magnesium Design and Research Institute, and always ensures that the equipment fully meets the design process requirements. In 2016, Hengfengtai successfully developed a fully automatic busbar pneumatic lifting frame, further advancing into the field of electrolytic aluminum intelligent equipment technology.

Electrolytic aluminum preparation, large-scale aluminum electrolysis pilot plant and other related industrial projects.

The anode lifting mechanism independently developed and designed by Hengfengtai has the characteristics of large lifting force, stable operation, safety and reliability, convenient maintenance, and can work in harsh environments with strong magnetic fields, high temperature and dust for a long time.

1. Air cut-off clamping device

2. The clamping force of the fixture is large

3. The tank body has strong rigidity

4. The upper and lower grooves are flexible and fast

5. Fully automatic frame with high efficiency

6. Perfect safety measures

7. Versatile and easy to use

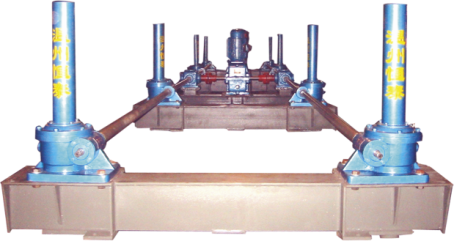

1. The unique and innovative design of the screw jack improves the carrying capacity and service life of the equipment.

2. The gears are processed by professional equipment, with higher precision and effectively guaranteed performance.

3. The guide frame is formed by one-time bending of the mold, which is more reliable in use and more beautiful in appearance.

4. Detachable telescopic sleeve is more convenient for maintenance and installation.

5. The optimal selection of lubricating oil and g

Copyright © Hengfengtai Precision Machinery Co., Ltd

Zhegan Wangbei No. 195235494654654

Zhegan Wangbei No. 195235494654654

Technical support: CNVP

WeChat official account